Products

- Plating Thickness

- Painting Thickness

Painting Thickness

- Laboratory Supplies

Laboratory Supplies

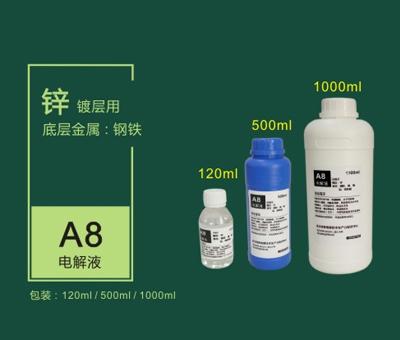

- Electrolyte Solution

Electrolyte Solution

- Calibration Standards

Calibration Standards

Electrolyte Solution

产品详情

A15 electrolyte is a special electrolyte for the test of electroless nickel plating on copper (chemical nickel test solution on copper plating), which is specially used for the electrolytic thickness gauge produced by Wuhan Materials Protection Institute (abbreviation of Wuhan Materials Protection Institute).

In addition to providing our company's electroless nickel plating test electrolyte on copper (electroless nickel test solution for copper plating), we can also provide other domestic and foreign friends such as German Fischer, German EPK, Nippon Electric Test, Japan Central Manufacturing Co., Ltd., For the substitute electrolyte for Coulomb film thickness meters from companies such as Kocour in the United States, please refer to the content in "Demand Selection".

Electrolyte characteristics:

The electrolyte should have a known, sufficiently long shelf life and should have:

a) When there is no applied current, it will not react with the metal coating;

b) The efficiency of the anode to dissolve the coating should be as close to 100% as possible;

c) There should be a detectable sharp change in the electrode potential as the coating is anodicly dissolved to the point of penetration and the exposed substrate area continues to increase;

d) The test area exposed to the electrolytic cell shall be completely wetted.

The electrolyte should be selected according to the covering layer, base material, current density and the flow of electrolyte in the test cell.

The electrolytes suitable for various electrodeposition thicknesses on a specific substrate are different using an electrolytic thickness gauge. Generally, the electrolyte should be selected according to the recommendation of the manufacturer. Refer to the content in "Requirement Selection".

The electrolyte is prepared using analytical grade reagents and distilled or deionized water. Small changes in solution concentration will not affect the accuracy of the results.

The storage life of the electrolyte is 24 months in an unsealed, airtight, dark, cool and ventilated place.

The electrolytes of the same plating layer cannot be substituted for each other due to different manufacturers or different substrates. Whether these electrolytes can be used in the manufacturer's instruments must be considered according to the manufacturer's recommendations or instructions, and for some special coatings. Whether a special electrolyte is required in combination with the matrix.