Service

- Technical article

Technical article

- Blog

Blog

- FAQ

FAQ

Reasons for the Difference in Thickness Values Between Electrolytic Thickness Gauges and Metallographic Microscopic Thickness Measurements

release time:2025-09-02publisher:Ren Xinghai

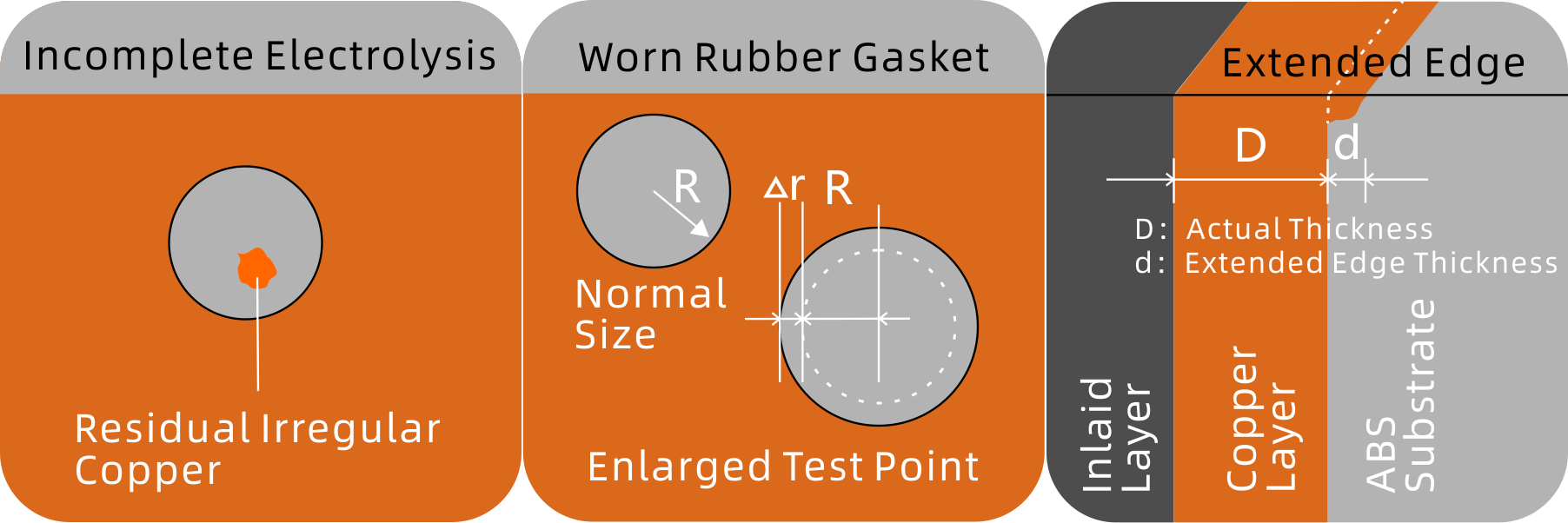

When testing the thickness of copper plating layers using an electrolytic plating thickness gauge and metallographic microscopic thickness measurement respectively, there are significant differences. The reasons are roughly as follows:

In short:

If the electrolytic test result is too thick, it is mostly due to the wear of the rubber gasket.

For plastic parts, if the electrolytic test point is complete but the metallographic result is too thick, it is usually caused by copper curling during metallographic preparation.

If you still cannot judge, you can send the sample to us for evaluation.